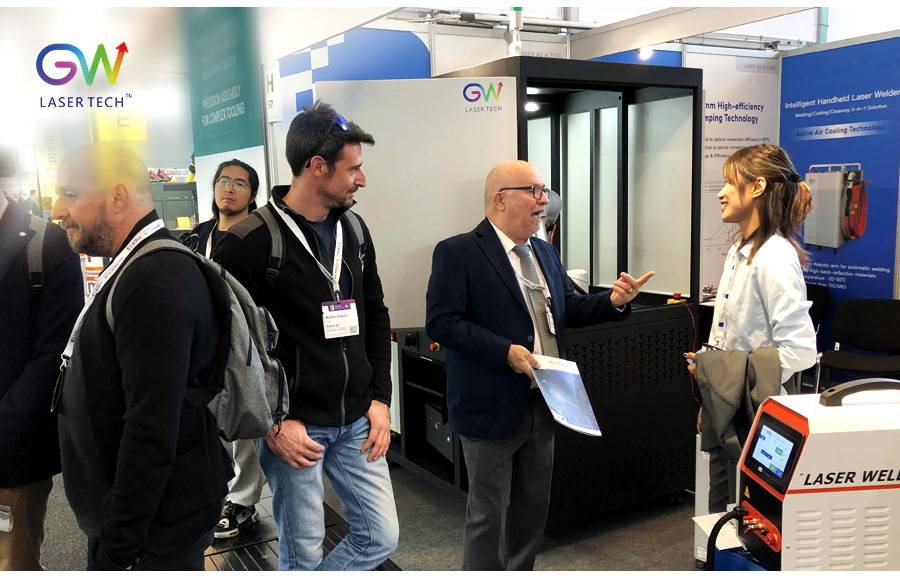

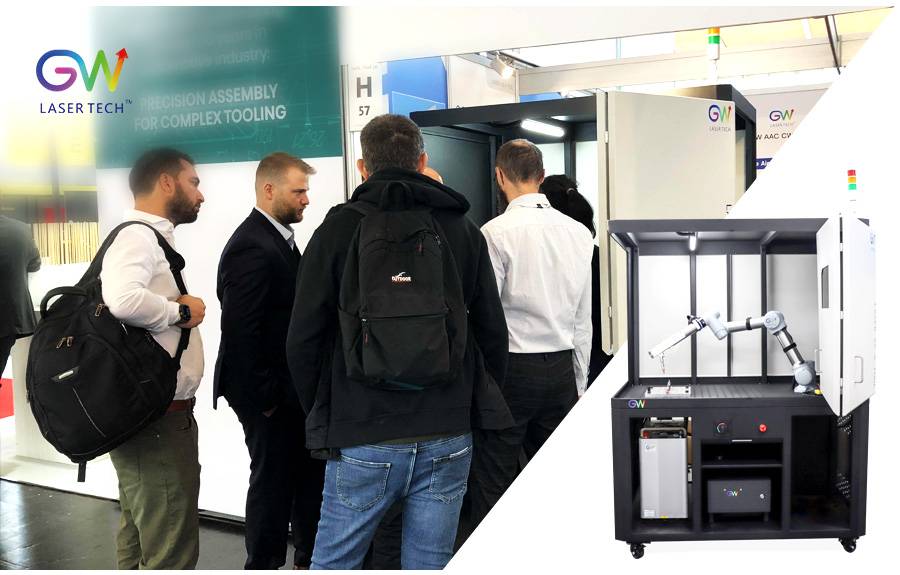

After the wonderful appearance of FABTECH 2024 in the United States, GW Laser went to Germany to participate in Euro BLECH without stopping, and once again set off a storm of laser technology. As the top event in the global industrial field, Euro BLECH has become the top event in the global sheet metal processing industry and the wind vane of the international market, GW Laser brought a full series of laser handheld welding, collaborative robotic welding platforms and other products to show the latest technology to the global users.

Globalization layout, more timely service

As one of the most developed regions in the world, the European economy has a huge market in consumer electronics, automotive and industrial markets, especially in Germany, France, the UK and Italy, etc. There is a huge demand in the field of metal processing, and as a leading brand of fiber laser in China, GW Laser has been deeply cultivating the European market for several years, and is equipped with exclusive service outlets in Europe and a professional team, winning the recognition of the European market for its high professionalism and enthusiastic service. GW has won the recognition of the European market with its high professionalism and warm service.

Full Series of Handheld Welding Re-emerges to Lead European Market in a New Direction

In March this year, GW Laser shockingly released the LW series of forced air-cooled handheld welding, and immediately received a warm welcome from domestic and foreign users. European customers, as one of the most loyal fan groups of GW Laser, shipped a record number of units within a few months, and with the LW forced air-cooled handheld welding design of the ultra-long 24h continuous welding, ultra-strong 3D phase-change heat dissipation, ultra-light, ultra-small and ultra-quiet design was highly acclaimed by a large number of users.

As one of the leading product lines of GW Laser, the handheld welding series products have created a “3D phase change forced air-cooled handheld welding” and “active air-cooling handheld welding” dual parallel, and have been recognized by a number of media (such as the laser business network, the laser home, OFweek, etc.) and won a series of awards. The innovative air-cooling technology provides a simpler and more flexible operating experience, which makes it a good choice for those users who pursue high efficiency and stability.

Accurate & Efficient, Enhance Productivity - Collaborative Robotic Welding Platforms

With the unique “All in One” concept, the GW Laser air-cooled handheld welder in a small volume, you don't have to worry about the constraints of a water-cooled machine, and the equipment can be moved around according to the processing scenarios. In addition, the faster and more stable welding experience greatly improves the part yield for users, reducing time-consuming grinding and rework. Powerful operating system, through a simple drag and drop can complete the welding processing sequence, so that the complex welding work more simple.

As a leading fiber laser manufacturer in China, GW Laser strives to discover and expand more global markets and serve more loyal users from all over the world by actively participating in more overseas market activities. “It is our mission to make lasers a universal tool for all. In the future, Brightwell Laser will continue to adhere to the “customer-centered” principle, serve the world with the most cutting-edge technology and industry-leading products, and bring more power to the development of the laser industry.