Fundamentals of laser 3D printing

Additive manufacturing (3D printing) of metal materials is in great demand in aviation, aerospace, navigation, vehicles, mold manufacturing, medical equipment and other fields. At present, the heat source used in the metal additive manufacturing process includes three high-energy beams of laser beam, electron beam, micro beam plasma and sintering heat input, etc., of which the laser beam is the most widely used high-energy beam heat source in the field of metal additive manufacturing. Compared with the electron beam and microbeam plasma heat source, the laser beam has the advantages of fine spot, low cost, and directional action to the specified material position, which can realize the instantaneous melting of metal materials and meet the requirements of fusion channel lapping and part forming.

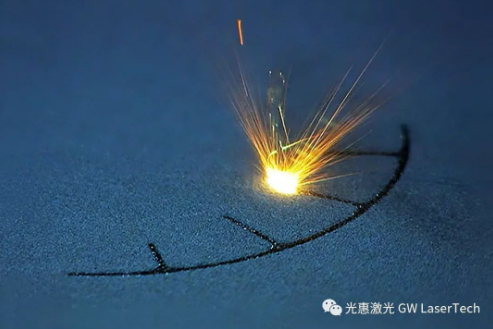

Lasers used in laser 3D printing include fiber lasers, semiconductor lasers, Nd:YAG lasers, and CO2 lasers. Different materials absorb different lasers of different wavelengths. In general, the printing polymer is mainly CO2 lasers, while the 3D printing of metal powders mainly uses fiber lasers. According to the different processing methods, laser additive manufacturing can be divided into selective laser sintering, selective laser melting, direct metal laser sintering, laser powder deposition, direct metal deposition and so on. Among them, selective laser melting (SLM) is currently one of the most widely used metal laser 3D printing technologies. The basic structure of a selective laser melting (SLM) printing device is shown in the figure. Before printing, the 3D model is layered and then the scan trajectory is determined. The first step is to evenly scrape the table with a spatula and lay a layer of powder on it; the second step, use a laser to scan a specific trajectory on this layer of powder to melt it and realize a layer of printing; the third step, move the table down one layer, and then cycle the above operations, so that the printing layer is stacked from bottom to top, so that the 3D parts to be printed are formed. In order to prevent oxidation, the entire process involves the extraction of air from the work chamber and filling it with inert gas.

▲ Basic principles of SLM printing equipment

The demand for lasers in laser 3D printing

The demand for lasers for laser 3D printing is mainly reflected in two aspects: on the one hand, power and power stability, on the other hand, beam quality and spot size. (1) Power and power stability 3D printing forming process mainly relies on the thermal effect of the laser, the laser intensity must exceed a certain energy threshold to melt the material, so more attention is paid to the average output power of the laser, which is not sensitive to the pulse mode of the laser, so it is usually used continuous fiber lasers, and the power is roughly distributed between 100W and 1000W. The larger the model, the more layers there are, and the longer the print time. The general duration ranges from a few hours to tens of hours. Therefore, there are high requirements for the long-term stable operation of lasers. If the temperature is high, the metal powder may overburn, or even cause other formed parts to remelt; the temperature is low, the metal powder is not melted thoroughly, the adhesion is not enough, and the shape of the formed member may not be maintained. Therefore, the power stability of the laser is crucial for print quality. (2) Beam quality and spot size Beam quality and spot size reflect one of the key parameters of printing accuracy. 3D printing is formed by laser beam scanning, the smaller the laser spot, the higher the accuracy of the scanning, the higher the resolution of the printed model, and the more delicate the surface of the printed part is visible to the naked eye. Beam mass is usually characterized by BPP or M2, the closer M2 is to 1, indicating that the better the beam quality, the more concentrated the laser energy, the smaller the impact on the surrounding heat; at the same time, the better the beam quality, the smaller the corresponding divergence angle, and the focused spot will be correspondingly smaller.

GW Laser and Fastform’s Exploration in the Field of 3D Printing

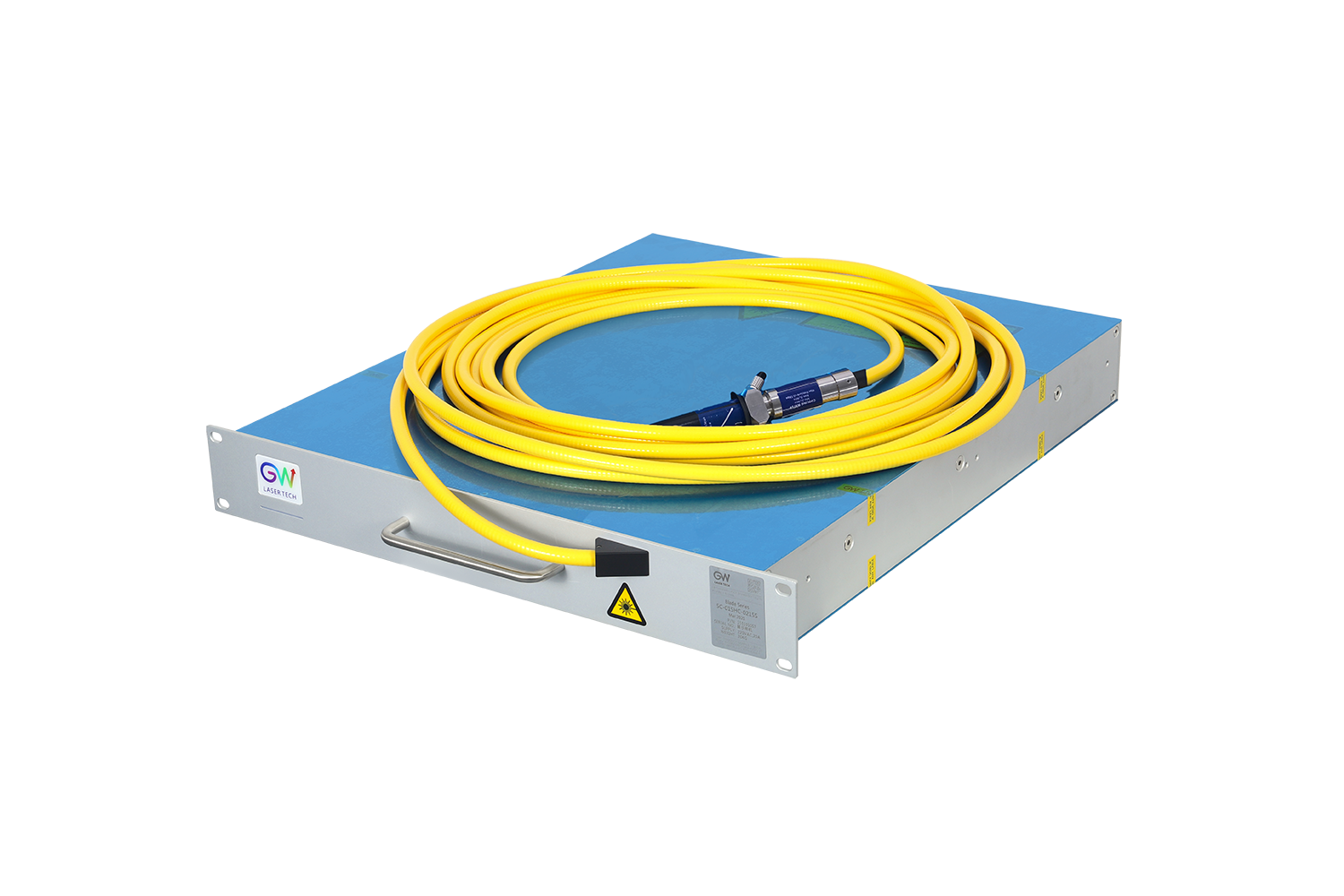

GW Laser Tech, as the global leader in high-brightness fiber lasers, with the rise of 3D printing technology, is also actively exploring in this application field, launching a 500W single-mode 10μm/14μm CW fiber laser for 3D printing applications, for medical devices, automotive parts, aerospace and other fields. Among them, 10μm and 14μm different core diameter size determines the size of the spot, mainly affecting the laser power density, that is, the light energy per unit area, under the same power conditions, the smaller the spot size, the greater the laser power density, and the high power density spot is suitable for printing high melting point or high reflection metal powder.

▲ GW laser 500W single mode 10μm fiber laser product advantages:

➢ Ultra-thin, lightweight design, 19 inches 1.5U height design, weight < 20kg, compact structure, small size, light weight, giving unparalleled integration convenience and flexible versatility.

➢ The product structure adopts a closed design, which greatly improves the overall reliability of the laser for the 3D printing environment, IP65 protection level, and can continue to operate in harsh environments such as high temperature, high humidity, and high dust.

➢ The maximum power is 500W, which is enough to form commonly used metal materials such as austenitic stainless steel, martensitic stainless steel, titanium alloy, nickel-based superalloy, aluminum alloy, magnesium alloy and so on.

➢ Good power stability, fluctuations per hour <0.5%, to ensure the process consistency of ultra-long printing.

➢ Good beam quality, M2<1.1, single-mode 10/14μm fiber output, small output spot, high printing accuracy.

FastForm is a company specializing in the research and development of 3D printing technology and equipment, which can provide top-notch rapid prototyping services and supporting solutions. It has established in-depth cooperation with GW Laser, and will conduct 3D printing tests and research on key components in aerospace, automotive models, biomedicine and other fields in the future. Launched FF-M140 single laser products, FF-M150 teaching special model, FF-M180D dual laser oral special model, FF-M300H 1000W high-power laser industrial model, FF-M500 dual laser model, FF-M800 four laser products, and all of them achieve mass production, support customized localization solutions. Independently developed multi-laser slicing and path generation software FastLayer. The equipment is fully automatically controlled and unattended.

▲ Mesothesonic manufacturing FF-M180D dual laser metal 3D printer This product has the following significant advantages: ➢ Two-way and variable speed powder laying technology, high powder utilization. ➢ Independent software development, one-click completion of automatic slicing and path planning. ➢ Built-in camera, can remotely achieve fully automatic control, unattended operation. ➢ The equipment adopts integrated welded structure, with strong stability and easy installation

▲ FASTFORM FF-M180D with GW 500W laser 3D printing products

The current situation and development prospects of the 3D printing industry

At present, 3D printing has entered the era of rapid prototyping, according to the statistics of the China Commercial Industry Research Institute, the machinery industry in the downstream application field accounts for the largest proportion in 2021, reaching 17.5%, followed by consumer electronics (16.6%) and automobiles (16.1%). With the rapid development of the consumer electronics and automotive industries, the application areas of 3D printing in these two fields will be further expanded in the future.

In terms of industrial scale, according to the projection of CIC, the average annual compound growth rate of 3D printing in 2021-2025 is about 26.59%, and it will reach 70.1 billion yuan in 2025. 3D printing covers three aspects: equipment, materials and services, of which printing equipment accounts for the majority. According to the data released by CCID, the scale of China’s 3D printing equipment industry in 2020 is 9.254 billion yuan, accounting for the highest proportion. At present, the price of 3D printing equipment is still relatively high, on the one hand, it originates from foreign patents and monopolies, on the other hand, because China’s 3D industry started late, the demand is small, and the degree of autonomy is low. With the upgrading and development of China’s high-end manufacturing industry, the development of technology and the decline of costs, China’s 3D printing industry will show a trend of increasing localization in the future. Close collaboration between device manufacturers is critical to driving the scale of 3D printing technology. Guanghui Laser not only focuses on the research and innovation of laser product technology, but also continuously explores in the field of laser processing technology, and is committed to helping customers solve application problems. As a leading manufacturer of 3D printing equipment in China, Micron Speed Manufacturing is familiar with all aspects of 3D printing, and has an experienced team of consultants to provide customers with high-end products in the field of professional 3D printing. In the future, Guanghui Laser will work with Us Light Speed Manufacturing to promote the application and development of laser 3D printing technology in China and help industrial upgrading.