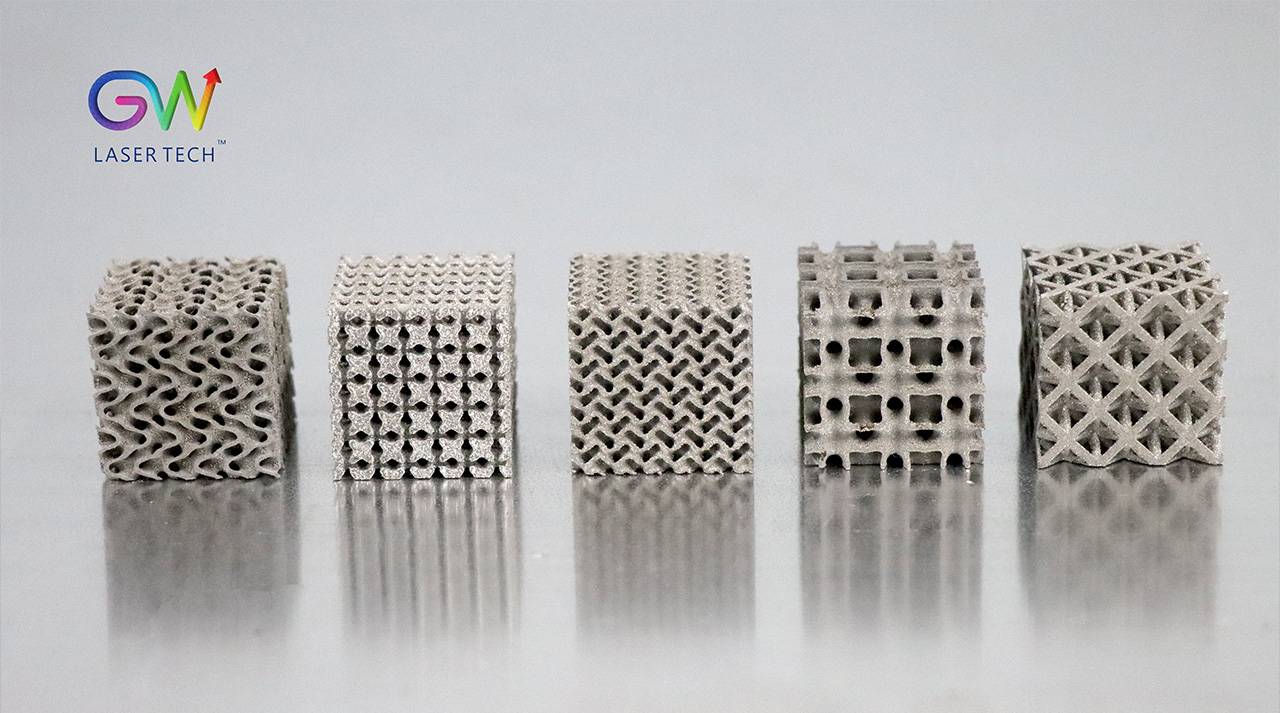

As technology continues to advance, metal 3D printing technology has grown into an important wing of the manufacturing industry. Compared with traditional processing, metal 3D printing technology can flexibly produce complex geometric parts through the use of photosensitive polymers, metals, and other materials, while also realizing outstanding advantages such as shortening production cycles, enhancing product performance, and reducing labor costs. Nowadays, with the increasing demand for high-performance materials in various industries such as aerospace, automotive, medical devices, consumer electronics, etc., the metal 3D printing market has great room for development.

GW Laser has launched a high brightness fiber laser for the 3D printing market, with power covering 300W~2000W, advanced optical technology, smaller core diameter, higher beam quality, and extremely high power stability, which brings breakthrough effect and experience to the metal 3D printing process.

01 High Beam Quality, Precise Control

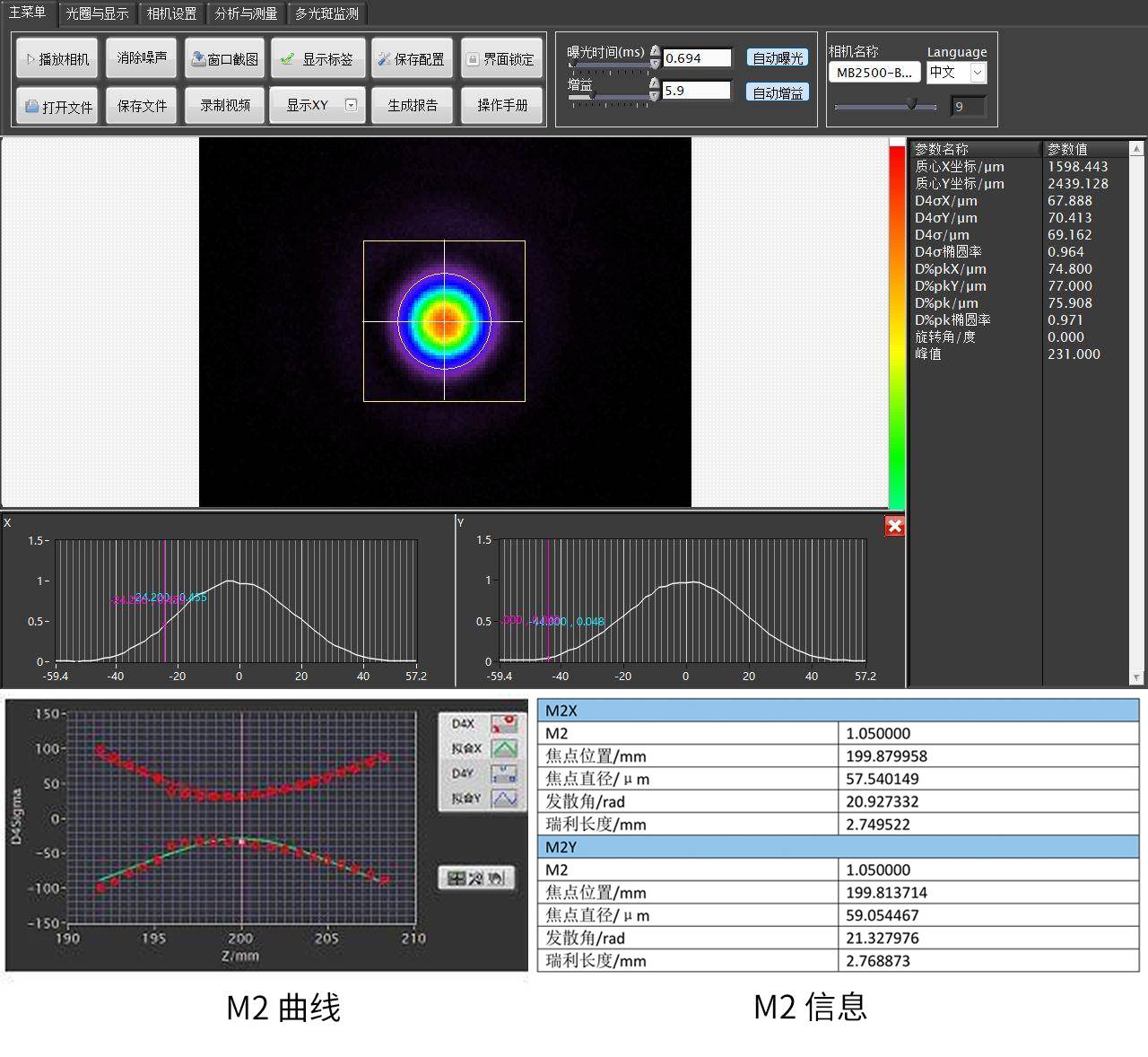

GW laser YLPS-500-W core diameter can reach 10um and 14um. Through the optimization of the key internal components, it makes the beam quality M²<1.1, the focusing diameter of the laser beam is smaller, and the power output is more concentrated. It not only accelerates the 3D printing speed, but also greatly improves the fineness of the processed material, ensuring precise printing, clear details and smooth surface.

02 High efficiency and stability, long time continuous output without pressure

In the process of 3D printing, the power output stability of the laser directly affects the layering and detail performance of the processed products, and even determines the success of processing.

Through the power closed-loop control system and internal thermal management technology, the closed-loop system can realize high-precision control of the laser power to ensure that the laser's power output is continuously stable, with the power stability of <±1.2%, to resist the interference of the internal and external environment and temperature changes. Even when the user is running for a long time or even in the case of large-sized parts, the consistency and reliability can still be maintained to ensure the quality of the product.

03 Low optical signal delay, high quality and high efficiency processing

GW Laser's high-brightness laser adopts a unique electrical control with low photoelectric delay efficiency and electro-optical response time <5us, which enables the laser to respond more quickly to the transformation of the control system commands, improves the printing accuracy and accelerates the 3D printing speed. At the same time, lower photoelectric delay efficiency in a long time in the high-volume 3D work, to ensure the stability and reliability of the equipment, greatly reducing the 3D printing process may be defective.

GW Laser's high-brightness laser adopts a unique electrical control with low photoelectric delay efficiency and electro-optical response time <5us, which enables the laser to respond more quickly to the transformation of the control system commands, improves the printing accuracy and accelerates the 3D printing speed. At the same time, lower photoelectric delay efficiency in a long time in the high-volume 3D work, to ensure the stability and reliability of the equipment, greatly reducing the 3D printing process may be defective.

0

0