"Three electric systems" (battery, motor, electronic control) is the core of new energy vehicles, is an important component that affects the performance of the entire vehicle movement, but also a measure of whether a car has a hard core strength. With the rapid growth of new energy vehicle sales, new energy vehicles three electric technology development is evident. In this process, laser equipment with high safety, high automation level, high precision and other advantages quickly released more market demand.

Compared with single-spot laser welding, GW Laser's FRM ring spot series lasers can achieve almost no spatter, no bursts, pinholes, pits, and uniform surfaces during the welding process, which greatly improves the production yield rate.

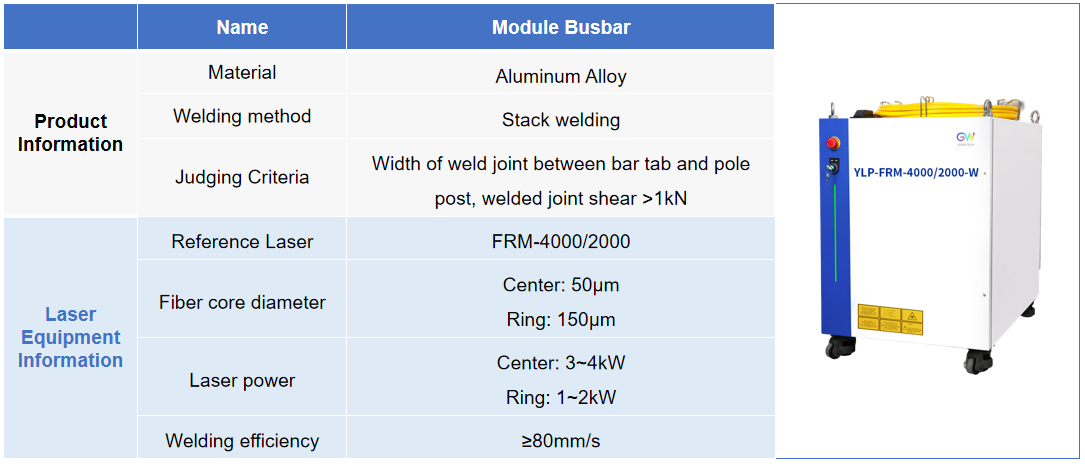

01 Square Battery Laser Welding--Busbar Welding

Busbar welding application is mainly the stack welding of aluminum alloy material, Guanghui laser FRM tunable beam laser series products in the welding process can easily achieve the welding speed ≥ 100mm/s, no spatter in the welding process, the weld surface molding is better. As can be seen from the cross-section, there is no porosity at the weld, uniform and consistent, the width of the weld joint can be up to 2.3mm, and the shear force of the welded joint between the bar piece and the pole column is >1kN.

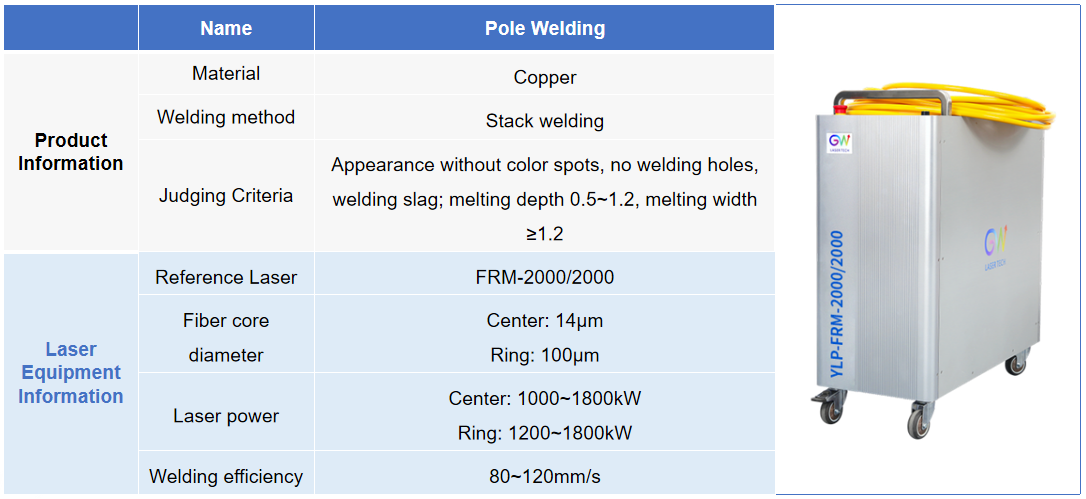

02 Square Battery Laser Welding--Pole Welding

Battery poles, i.e. the positive and negative poles of the battery, generally use aluminum for the positive pole and copper for the negative pole. When welding, in order to meet the design requirements of tensile force and electrical conductivity, Guanghui FRM Tunable Beam Fiber Laser can achieve: Aluminum-Aluminum structural welding of electrode posts, copper-copper structural welding of higher stability, less spattering, and thus improve the welding yield.

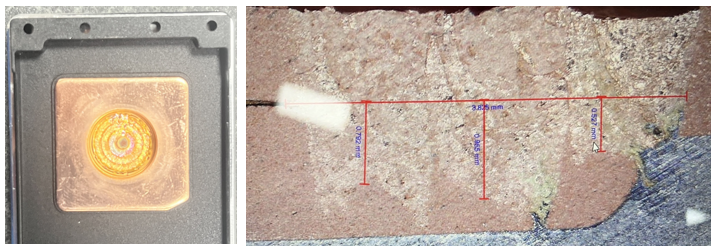

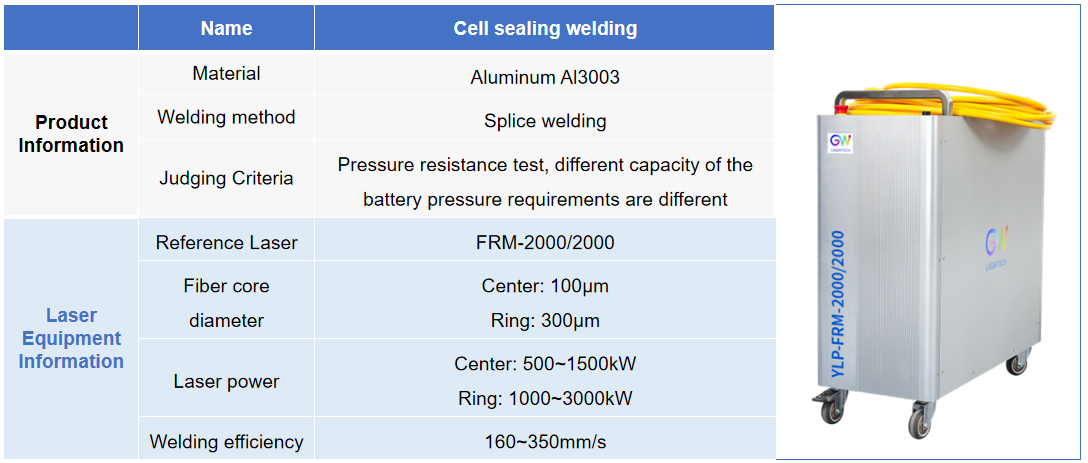

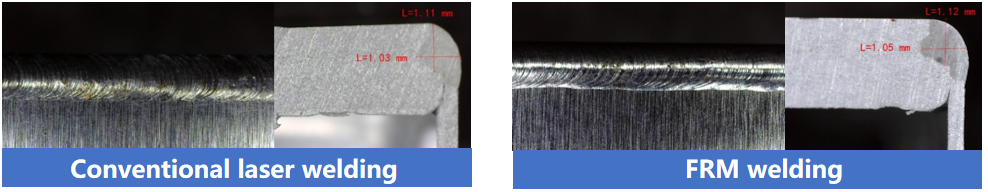

03 Cylindrical battery laser welding--seal welding

The main material for seal welding is top cover piece or core shell (aluminum Al3003), GW Laser FRM products in the seal welding process, welding speed ≥ 200m/s, melting depth > 1.0mm, and the pole and plastic parts are not burnt, no false welding, no welding slag, no burst hole at the welded joints, and no porosity, no crack inside the weld.

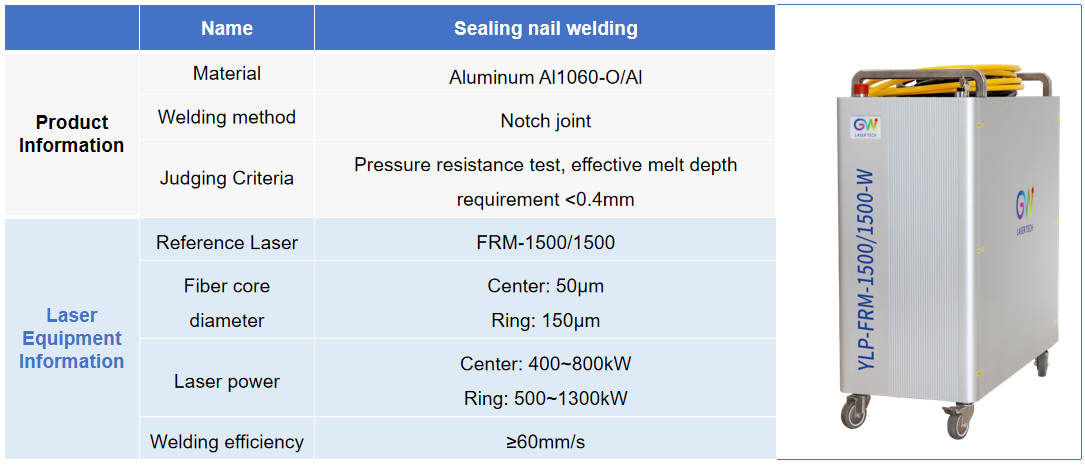

04 Cylindrical battery laser welding--Sealing nail welding

Sealing nail welding is also called liquid injection port welding, when the electrolyte is injected into the battery, it is necessary to plug the plug and immediately carry out laser welding to seal it, thus isolating the whole core from the external environment and forming an airtight electrochemical system for the whole core.FRM series products can make the welding speed ≥60mm/s, with no spattering during the welding process, and the welded seam is beautifully shaped and even with no blown holes, and the yield rate of the line is greatly improved.

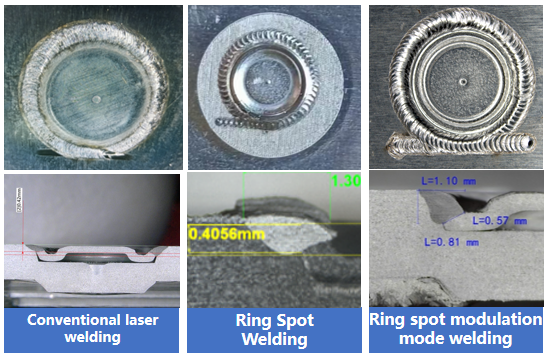

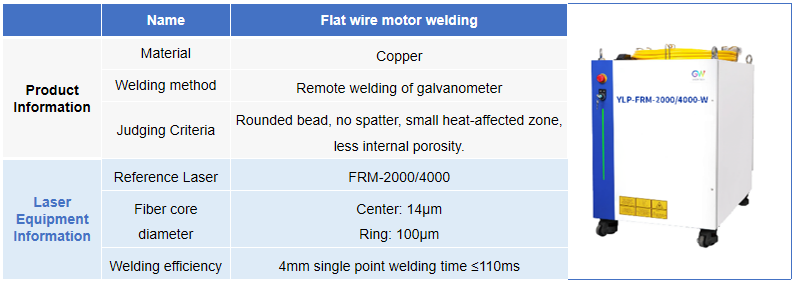

05 Flat wire motor welding

Copper, as the main material of electric drive motor system, its absorption rate, thermal conductivity and other factors of the material itself lead to a lot of spatters and air holes easily during processing. GW laser FRM products can effectively correct the shape of the keyhole, maintain the stability of the keyhole, and improve the welding quality and welding efficiency of flat copper wires.

GW Laser's leading position in the field of new energy battery welding is not only reflected in the excellent product performance, but also in the attention and service to customers. We will always adhere to the "user-centered", through unremitting technological innovation and quality service, and work closely with global users to provide customers with high-performance, high-efficiency laser solutions, injecting a new technological direction for the industry, and inspire unlimited possibilities.

0

0