Recently, many parts of the country frequently issued heavy rainfall and strong high temperature weather warnings, the use of the laser environment should pay extra attention. To this end, GW Laser tips you, do a good job of laser routine maintenance and inspection, checking for potential safety hazards, circuit safety and other issues.

01 waterproof moisture, avoid condensation

The high temperature and humidity in summer can easily cause the internal components of the equipment to overheat or moisture, affecting the stability and accuracy of the laser. Ensure that the working environment of the laser is kept dry and ventilated and at a suitable temperature. It is recommended to place the laser in an environment where the temperature is controlled at 20-30℃ and the humidity is 40%-70%, and ensure air circulation.

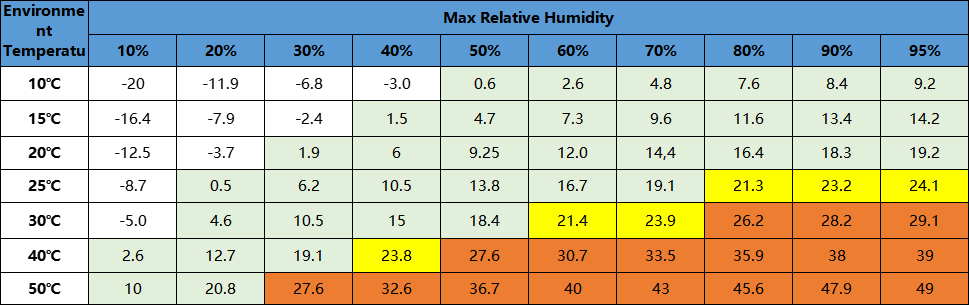

It is necessary to set the cooling water temperature in accordance with the actual temperature and humidity environment at the site, and make sure that the temperature of the laser cooling water is set higher than the corresponding dew point temperature, otherwise it may cause condensation on the laser.

(Dew point table)

02 Safe use of electricity, waterproof and fire prevention

Thunderstorms and other weather are frequent in summer, the power grid may fluctuate frequently, pay attention to the stability of the power supply of the equipment, and it is recommended to connect a voltage regulator for use. Regularly check the cables and joints to avoid any safety hazards such as breakage, water soaking, leakage and short circuit. Pay attention to the equipment power load and operating load, long time high load operation will make the laser internal temperature rise, accelerate the aging of the parts. It is recommended to appropriately reduce the processing intensity and use time to avoid causing safety hazards.

03 Regular inspection, regular maintenance

In summer, the humidity in the air is relatively high, and the lenses are more likely to be stained with water mist and dust, so it is recommended to check the protection lenses regularly and replace them in time when they are dirty or abnormal. In addition, the maintenance of the laser cooling system is also crucial. Regularly check the cooling system operation status, fan, heat sink, water-cooled tube, dust cover and other components and clean. Regularly clean the filter and replace the coolant to prevent deterioration.

In summary, summer laser maintenance needs to pay attention to the working environment, electricity safety, cleaning and maintenance and other aspects of regular inspection, regular maintenance to ensure that the laser in the summer high temperature and humid environment stable operation. If you encounter any problems, please feel free to contact GW Laser: sales@gwlaser.tech, we will be the first time for your service.

0

0